Improve image file management for machine vision with QualityWorX

Machine vision systems are valuable tools for quality inspection, but how are you using the massive number of images and amount of data they produce? Pass/fail is not enough and provides limited traceability. QualityWorX Vision allows you to:

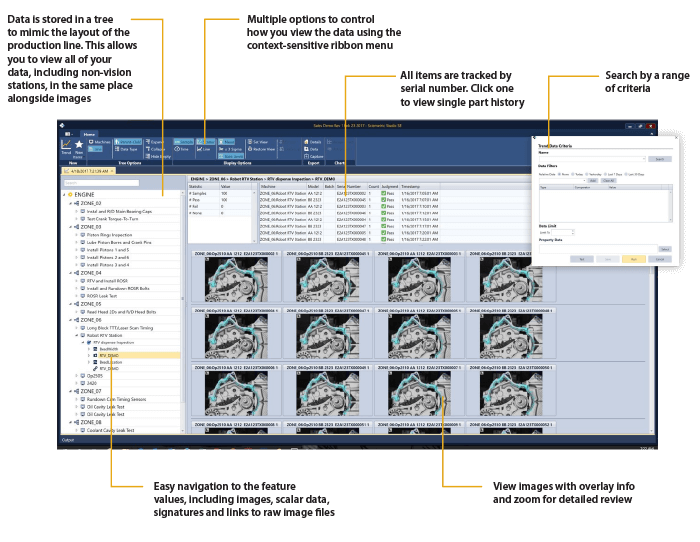

- Collect and store in a single database scalar data and images, including image overlay information, from multiple cameras, traceable to a part serial number

- Capture images and data for systems with limited or no storage capability at the camera level

- Avoid the need to run down to the plant floor with USB sticks to move images from plant floor system to your system for reanalyzing

- Use manufacturing analytics to enable fast retrieval, review and analysis of image and scalar data

- Scale from single station to all cameras to all inspection systems on the plant floor (e.g., leak test, fastening systems, in-process test stations, etc.)

READ THE BROCHURE

Store, retrieve, analyze images and data from Cognex® In-Sight® cameras

QualityWorX Vision for Cognex allows manufacturers to organize and manage images and data from In-Sight cameras into a single, accessible database.

Stored by part serial number, the data captured in QualityWorX includes not only images but also all the scalars from the test process. The solution enables the aggregation of vision data with that of other processes on the production line to provide a more complete part history.

Learn more about QualityWorX

for Cognex® In-Sight® cameras

QualityWorX brings your data together so you can put it to work

Images and data work together in consolidated part history

Smart factories today generate reams of data from processes and tests across the production line. Being able to collect, store, analyze, and report on all the data means you can find the root cause of problems faster and solve them more reliably so they don’t affect production down the line. Our suite of QualityWorX manufacturing analytics software lets you include machine vision images and data in a full part history so vision systems are no longer a silo.

Manage all your data in one place

Data is in our DNA. Leading discrete manufacturers have implemented our QualityWorX data management and manufacturing analytics solution to turn information into insight on their production lines enterprise-wide. Our solution doesn’t just collect data from vision inspection systems – almost any process or test today can be tied into QualityWorX, giving our customers a complete, consolidated picture of quality and productivity across their connected factory.

LEARN MORE ABOUT OUR MANUFACTURING DATA SOLUTIONS

How to lever the data from machine vision inspection applications to improve quality, productivity

Vision systems are valuable tools for quality inspection, but how are you using the massive number of images and amount of data they produce? This e-book explains why you should integrate machine vision output with the rest of your process data for a complete picture of production health.

DOWNLOAD THE E-BOOK

QualityWorX Vision in action

From barcodes to inspection applications, vision systems are probably a big part of your assembly lines. Check out this video to see how QualityWorX Vision helps you collect, store, analyze and report on this critical data for faster issue resolution and decision-making you can trust.

Watch the video

Experience an award-winning solution

Our QualityWorX Vision solution has been repeatedly proven one of the best image and data collection and analysis solutions for machine vision applications on the market, and recently won Gold at the Vision Systems Design 2018 Innovators Awards.

READ ABOUT OUR GOLD AWARD FOR QUALITYWORX VISION

REQUEST A QUOTE: QUALITYWORX VISION