Data-driven insight to ready the production line for Industry 4.0

A key principle of any digital journey for a manufacturer, whether or not they are in the automotive supply chain, comes down to making effective use of production data. Learn how to ready your production line for Industry 4.0 with data-driven insights in this article, contributed by Sciemetric's Manufacturing IT Manager, Patrick Chabot.

Who should be your digital-transformation champion?

We often talk about “silos” in manufacturing, referring to process and test data trapped on the production line that could otherwise be used to drive improvements in quality and yield. But as we all grapple with this thing called Industry 4.0, the silos that often cause the most problems are the ones that exist between people, not machines. Read this article by Jeff McBee, Regional Sales Manager at Cincinnati Test Systems, to help identify who best to appoint as champion of digital transformation initiatives in your plant and which questions you should be asking yourselves as you devise your approach to Industry 4.0.

events

The Battery Show 2019

We will be at The Battery Show 2019 with our partners, Cincinnati Test Systems presenting our latest technologies for testing and monitoring operations on your production line. Our combined solutions range from a wide variety of leak test solutions as well as solutions for virtually any in-process test on your production line.

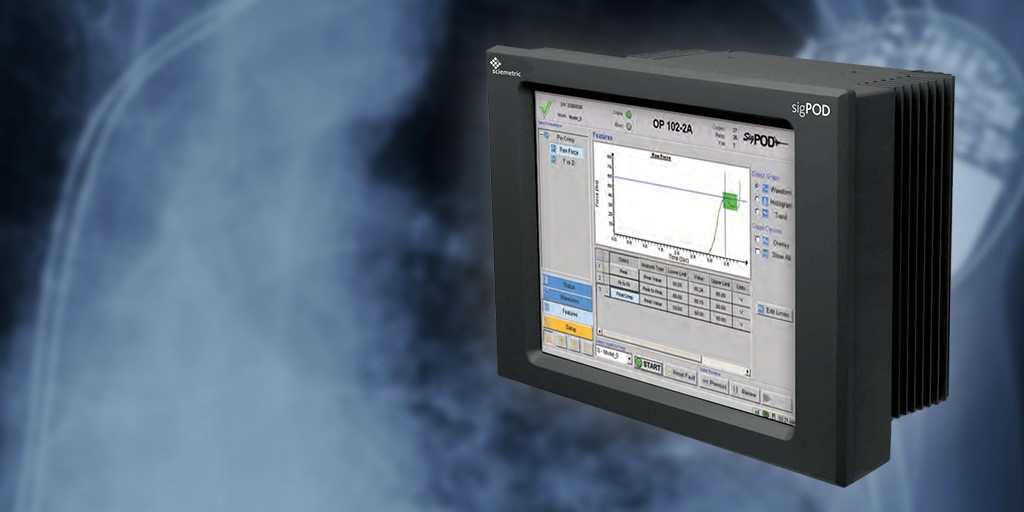

SPC can catch a problem, but only signature analysis can fix it fast

Joe Ventimiglio discusses how SPC (statistical process control) remains an effective means for manufacturers to spot production problems, but for effective quality management and to quickly trace root cause, you need more – digital process signature analysis.

Quality assurance is falling short? Consider a retrofit before a rip-and-replace

How much big data do you need?

The idea of big data and Industry 4.0 can overwhelm manufacturers—but it doesn't have to. The first step towards Industry 4.0 doesn't have to be a giant leap. At it's core, it's just about using your data in a productive way. Jeff McBee, Regional Sales Manager at Cincinnati Test Systems, offers 7 questions to self-diagnose your need for data-driven analytics in the latest issue of Manufacturing AUTOMATION.

events

The Assembly Show 2019

We will be participating in The Assembly Show with our partners, Cincinnati Test Systems. Visit us at Booth #1105 for the latest in leak test, in-process test and production data analytics technology.

Improve crimp testing with non-destructive methods

Five Ways Production Data Drives Plant Efficiency

This article, by Cincinnati Test Systems’ Vice-President of Global Sales, discusses 5 ways product data can be applied across production to improve overall plant efficiency.

resources

Sciemetric EDGE 422 数据表

Sciemetric EDGE 422 是一款高速数据采集设备,可在需要执行精确的时间关键型测量时使用。该多合一系统自身带有处理器,以及超紧凑型的模拟和数字功能。

Tags: