Sciemetric’s manufacturing analytics solutions provide everything you need to monitor and improve product quality and make informed decisions on your production line every day. Gaining access to data-driven insights starts with collecting data from critical-to-quality tests and processes on the production line. Sciemetric’s solutions are flexible and scalable, allowing you to connect one station, many stations, or a whole line—it’s up to you! This data is then stored and formatted in an accessible database, where it becomes available for analysis and practical reporting to solve problems and make optimizations to your manufacturing processes.

Step 1: Manufacturing Data Collection

Sciemetric’s manufacturing analytics solution consists of QualityWorX for data collection and Sciemetric Studio for analysis and reporting. QualityWorX collects data of any type from nearly any test or process (such as torque tools, presses, and leak tests) and consolidates it in a single, centralized database, by part serial number. With QualityWorX, you can build a digital history of each part including key assembly processes and their results for full traceability.

Sciemetric offers a scalable solution, able to connect as few as two stations or a whole line into a centralized database. Data is organized to mimic production line flow and can be analyzed by serial numbers, parts, stations, lots, shifts, etc., making it quick and easy to access the data you need when a problem occurs.

Step 2: Manufacturing Data Analysis

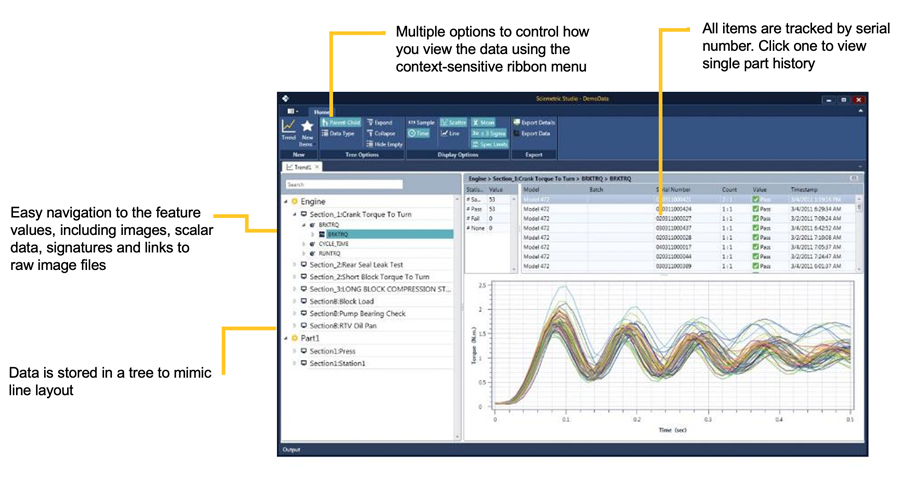

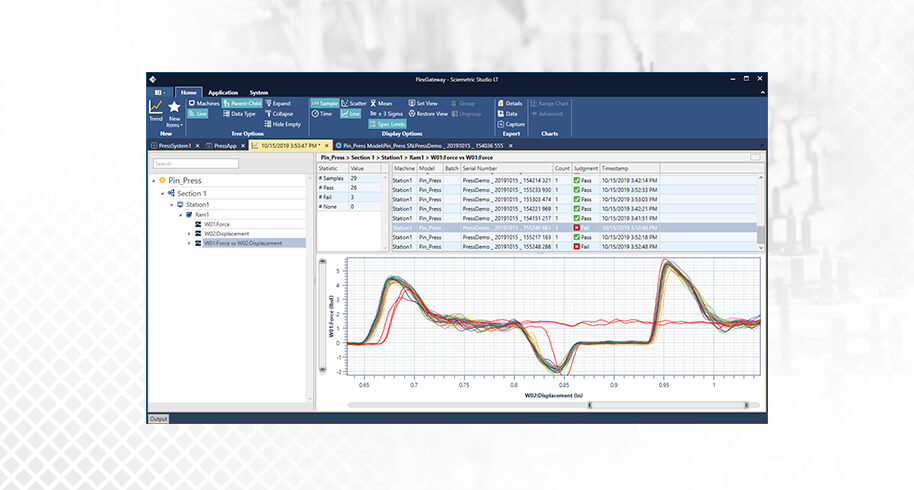

Sciemetric makes your production data accessible and practical. Sciemetric’s manufacturing analytics software, Sciemetric Studio provides you with real-time access to an organized repository, with all of your data accessible in the same place. It includes a flexible set of analysis tools to meet your requirements, from quick, simple visualized charts and manufacturing reports to more complex analysis.

Whether you need to identify the root cause of a specific quality problem, or want to find ways to optimize your processes, or use advanced “what if” analysis capabilities to test new parameters and limits offline, you can do it using Sciemetric Studio! Sciemetric Studio also includes statistical process control software, making it simple to use SPC reports to set test limits and alerts for real-time defect detection.

Step 3: Take Action with Your Manufacturing Process Data

The ability to collect, store, analyze and report on every critical-to-quality process on your line delivers huge benefits, affecting both efficiency and budget. When you’re faced with a quality issue, Sciemetric’s manufacturing data analytics enables you to identify the problem and figure out how to fix it in as little as minutes or hours—not days or weeks.

Sciemetric has worked on thousands of manufacturing lines across the globe. Using Sciemetric’s manufacturing analytics solutions, we’ve enabled manufacturers to:

- Use data to respond quickly and reduce downtime

- Eliminate guesswork and use data to set test limits

- Optimize cycle time

- Automate defect detection and quality control (with switch to digital records)

- Improve first time yield, saving millions per year

- Limit the scope of recalls and quarantines

- Get full traceability and a digital assembly history for each part

- And much, MUCH more!

Work with the Experts in Manufacturing Quality Analytics

Sciemetric is an expert in data analytics in manufacturing industry, having worked with manufacturers across the globe for over 40 years, helping them make better use of their production data to improve product quality and enable continuous improvement.

If you have questions about data collection and analytics on your production line, contact the experts in data analytics and manufacturing! Our team has the knowledge and expertise to help you identify where you need greater insight on your line and how to make the most of your analytics.