Industry 4.0 has manufacturers under pressure to increase production line output, profitability, and efficiency. Those who want to improve manufacturing processes often find that they are limited by:

- The capacity of machinery

- Downtime for repair and maintenance

- Production defects that result in scrap or rework in the repair bay

- Test stations that lag the pace of production and create bottlenecks

The good news is that increasing manufacturing production efficiency doesn’t require a costly rip or increasing your workforce. All these issues can be addressed by making better use of the reams of manufacturing data generated on the production line every day through key processes and tests. Learning how to utilize real-time production data will help you achieve greater accuracy and better visibility in your reporting and analysis, leading to improved efficiency, yields, and profitability.

Sciemetric’s vendor-agnostic manufacturing data management system and manufacturing analytics tools help you optimize test cycle time and provides easy visual analysis that can be deployed quickly for a rapid return on investment.

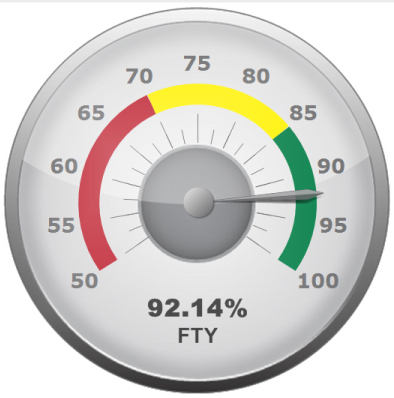

Check out our blog post, Overall Yield vs. First Time Yield: Which Offers the Greatest Return?

How to increase manufacturing production using real-time production analytics

Reduce production defects and increase manufacturing production, profitability, and efficiency using digital signature analysis. Sciemetric’s tools and expertise provide 100% real-time process manufacturing process control to verify every part at each critical quality step, helping you reduce downtime and increase productivity and yields:

- Find and remove defects from production as they occur.

- Quickly correlate downstream defects to upstream processes to reduce downtime.

- Quickly trace the root cause of defects. Each part becomes a ‘Batch of One’ to limit the scope of a quarantine.

- Predict the sources of defects before they occur.

- Eliminate the need for destructive testing.

- Cut precious seconds from test cycles without compromising quality.

Increase manufacturing efficiency with Sciemetric

Sciemetric provides your team with the clarity and insight to overcome the barriers to increasing production output, whether it’s related to unexpected downtime, poor FTY/FPY/FTT, or test stations that can’t keep pace with production.

- Use our sigPOD universal part test and process monitoring systems for that real-time insight on each process and test station.

- Capture and store all this production data with our QualityWorX suite of data management and manufacturing analytics software to reduce the time for problem resolution.

- Further analyze this data with Sciemetric Studio, our next-generation analytics software for smart manufacturing.

Case Studies

Leading automotive OEM increases engine production with manufacturing analytics

At one plant, the OEM experienced electronic throttle failures at the end of the line engine test, a time at which it is expensive to address. By using Sciemetric’s data management and manufacturing analytics tools, the OEM’s team found the two reasons for the failures and fixed the upstream process issues to eliminate them. They were also able to run the criteria against quarantined parts to determine which ones exhibited the same factors.

The result? The 1.27% failure rate was reduced to 0.07%. This may sound small but it resulted in an additional yield of 170 engines a month, which added up to significant cost savings.

Higher throughput, better quality,

at a lower cost

When a manufacturer’s line had to gear up to take on the production of another plant, the Sentinel 3520 enabled them to meet the challenge.

The 4x faster cycle time made possible with this instrument reduced the number of required leak test stations by half, allowing them to incorporate the test into the line.

APPLICATION NOTE: LEAK TESTING CARBURETOR ASSEMBLIES