Contributed by: Sciemetric Staff

This past year has certainly thrown the manufacturing industry into some unexpected situations. Due to these new circumstances, budgets and timelines have been under an ever-increasing microscope. This sentiment certainly rings true when we looked back at the most-read content from our blog over 2020. Topics around improving efficiency and effectiveness seem to be top-of-mind—with the below posts gathering the most attention from our customers.

We’ve collected them together here in hopes they may help you in setting up your production line for success in 2021!

1. Overall yield vs. first time yield (FTY): Which offers the greatest return?

Yield is an important performance metric on manufacturers’ minds. At Sciemetric, we urge manufacturers to not only look at yield, but to look at first time yield (FTY). This blog post discusses the difference between the two metrics, and how implementing solutions in order to improve FTY saved one of our customers $3.83 million per year. Read the blog to learn how this strategy could help improve your production efficiency—and bottom line.

2. Why relying on end-of-line is bad for your bottom line

End-of-line tests remain popular with many manufacturers—however due to their high level of complexity, these tests can result in false passes that can cause serious problems in the field, and serious consequences to your bottom line. Read this blog post to learn about the helpful additions to end-of-line testing that have saved our customers millions.

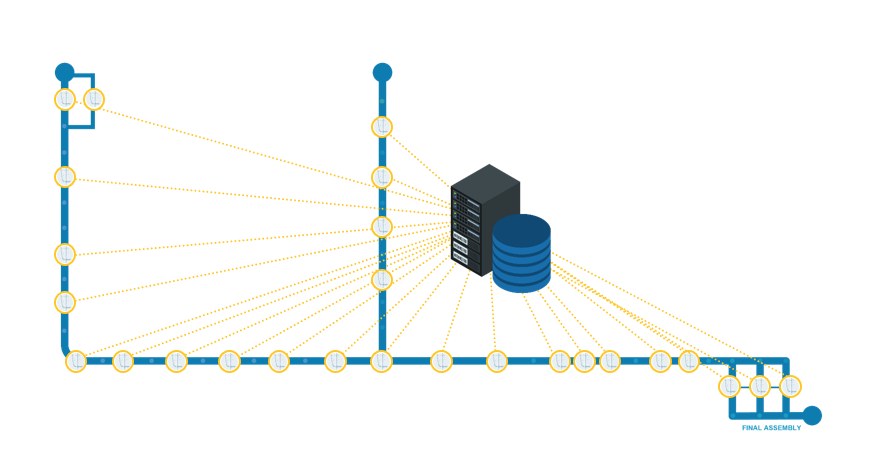

3. How to effectively store and manage machine vision images and data

The information generated by machine vision systems puts a whole new spin on the term “big data.” The raw image files output from vision systems are huge, and manufacturers can generate terabytes of image data in a month—even in a week! So, what do you do with all this data? Read the blog post to find out!

4. Manufacturing analytics: So you’re collecting data, but can you use it in a recall?

It’s when manufacturers are faced with a recall or warranty claim that they realize data collection alone has little value if they can’t easily access and analyze it. Learn how we helped one manufacturer of agricultural machinery use their data to improve their root cause analysis time from weeks to minutes!

5. How to improve defect detection during press operations

Like any common manufacturing operation, a press operation can be monitored to prevent flaws and defects from impacting part quality. In this series, we will dig into how press defects can be found using digital process signature analysis software and what to monitor, with examples from actual press operations.

Looking to make improvements on your line in the coming year?

Contact us to discuss how process monitoring and data analytics could be used to boost your line’s efficiency and product quality, with solutions designed to meet your specific needs.