Leak Test

Sciemetric data analytics tools enabled engine manufacturer to link EOL failure to cracked check valves—see how!

Go beyond station checks to improve product quality and line efficiency: The value of process monitoring and data analytics

5 ways to improve your production line in 2020

Battery pack leak test: The challenges of getting an honest result

A variety of factors make it difficult to simulate the exact leak conditions battery packs will experience in the field, but there are strategies to achieve an effective battery pack leak test. Here are two of the key challenges you are likely to encounter with battery pack leak testing and strategies to overcome them.

How to catch faulty fuel rail insertion with digital process signature analysis

Tearing down an engine to find a problem when it fails an end-of-line test is costly and time-consuming. It’s much better to identify a quality issue upstream on the production line where it occurs. Learn how an automaker used digital process signatures to adjust their fuel rail insertion parameters to catch faulty insertions before they reach the end of the line.

Factors in identifying proper test pressure for your leak test

A chief goal when it comes to optimizing any leak test is to ensure if the cycle time of the test can keep up with the pace of production. One factor in optimizing the test so that it can cycle as many parts as quickly as possible with an acceptable range of repeatability and reliability is test pressure. Consider the following factors when identifying proper test pressure for your leak test.

Large volume leak test: 4 tips for a reliable and repeatable test

Performing a leak test on big parts poses big challenges. But, as is the case with any leak test scenario, if you know and control your variables, you can control the test. Here are 4 tips to help you achieve a reliable and repeatable leak test.

5 tips to improve your production line in 2019

With each new year, many of us take time to reflect on our past and set goals for the future. Why not apply the same exercise to your production line? To help you improve your production line in 2019, we have provided the following tips, chock full of insights from our experts.

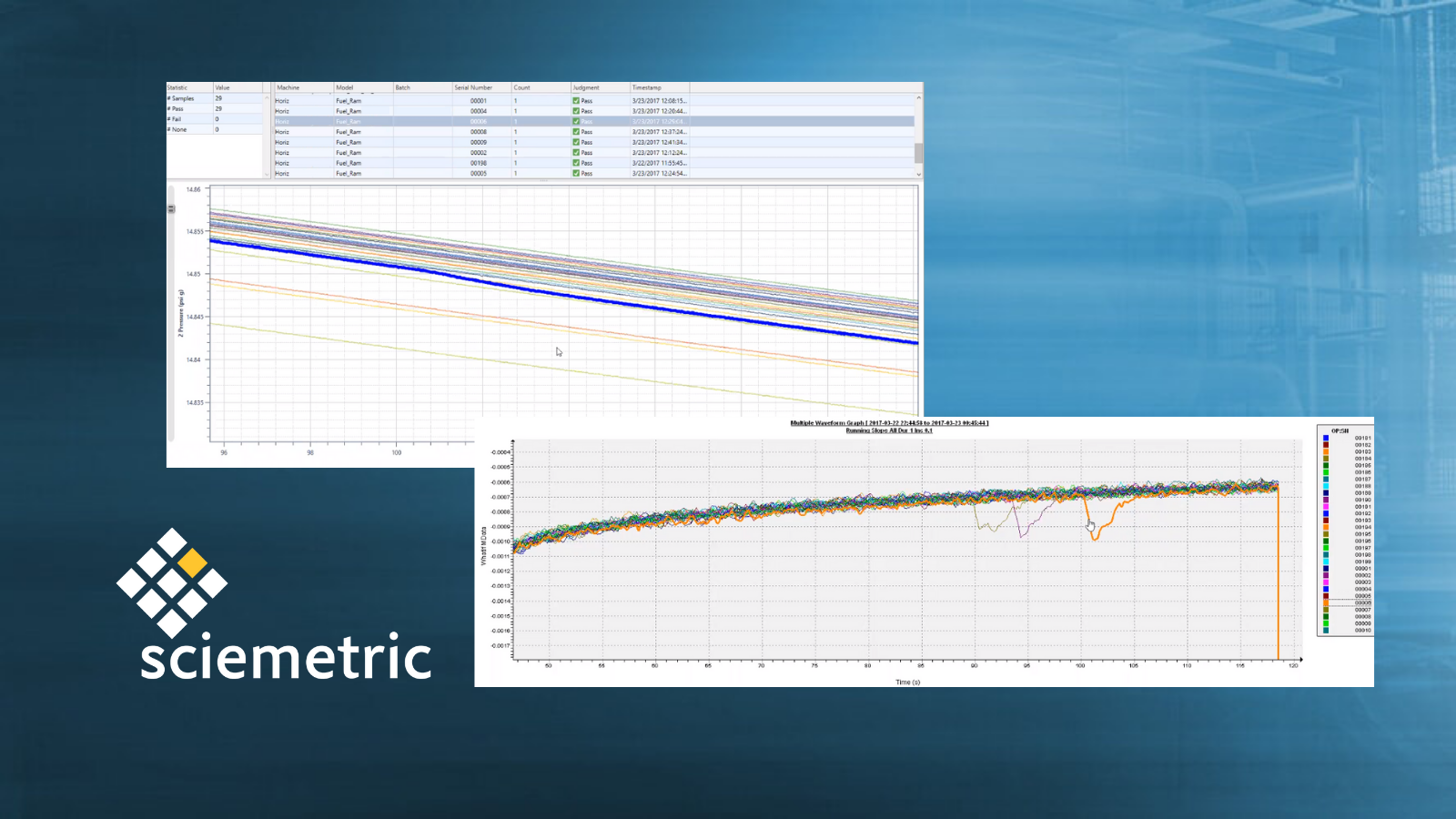

Data visualization and analysis provides double-digit gains in leak test cycle time and FTT

Many manufacturers face the costly problem of a lagging leak test cycle time. With constant pressures on production, line managers have no choice but to run parallel test stations to maintain production quotas. More often than not, the answer is simple—use your leak test data. Here’s how one customer did it.

8 ways we can help you improve your leak test

Learn about the successes we’ve helped our customers achieve—and how we can help you achieve the same success on your production lines!