Considerations when digitizing paper-based records, automating defect detection and quality control on the production line

7 production data gaps that are slowing down manufacturing engineers

Monitoring for weld expulsion: A prime cause of weak welds, defects

Set up your line for success in 2021: Lessons for improving product line efficiency and effectiveness

Due to the circumstances of 2020, manufacturing budgets and timelines have been under an ever-increasing microscope. This sentiment certainly rings true when we looked back at the most-read content from our blog over 2020, where improving efficiency and effectiveness seem to be top-of-mind. Set your line up for success in 2021 with these tips from our most-read posts of 2020, here!

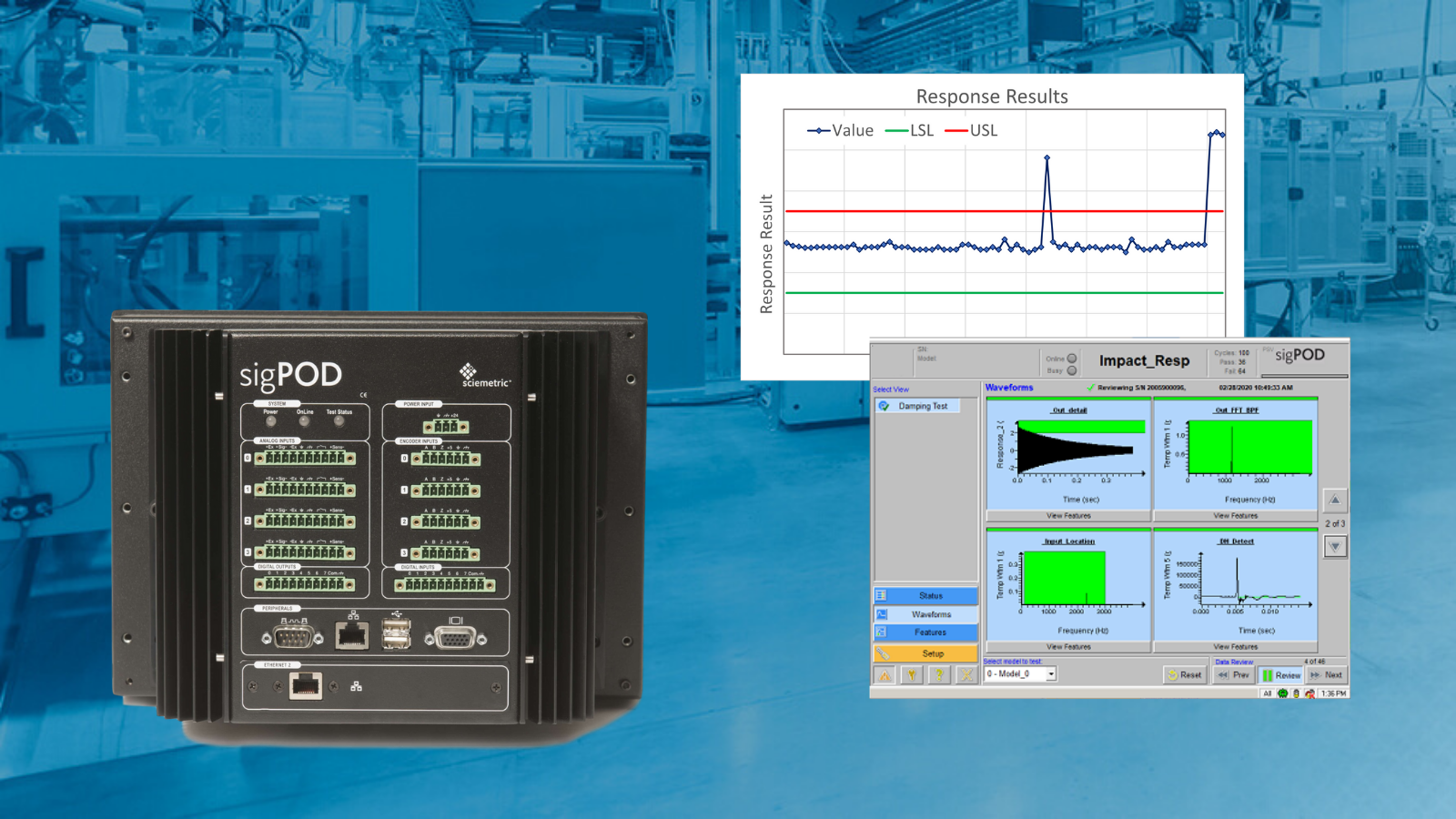

How to detect delamination of brake pads using impact response testing

Brake pads can be constructed of a variety of materials, which need to be securely bonded to a backing plate to function properly. Failure to ensure a proper bond between these materials can result in costly scrap and rework. In this blog post, Sciemetric's Jason Koval discusses how to detect delamination of brake pads using impact response testing.

Go beyond station checks to improve product quality and line efficiency: The value of process monitoring and data analytics

Machine data versus part data: pros and cons | Manufacturing Data Series, Part 3

When we talk to manufacturers, sometimes we find that the difference between machine data and actual part production data has gone unnoticed. While both have their role to play, one is not a substitute for the other, as they don’t measure the same things. This blog post discusses the pros and cons of these different data systems to help you decide what's right for you.