Manufacturing Management

Optimize manufacturing test cycle times using digital process signatures

Set more effective control limits on production tests using digital process signatures

Optimizing limits on your manufacturing test processes eliminates false failures and reduces the risk of giving bad parts a passing grade. This blog post discusses how to use digital process signatures to set more effective limits, more quickly, to produce higher quality parts, lower scrap/rework rates, and experience fewer recalls or warranty claims.

Improve manufacturing defect detection using digital process signatures

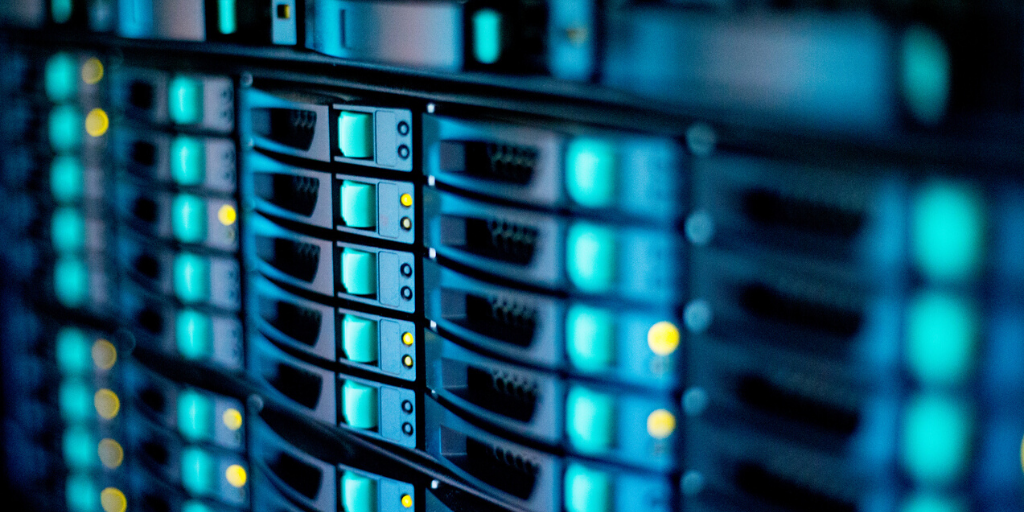

How the network edge can help your plant or industrial operation optimize cloud resources

Many manufacturing and industrial facilities have chosen to recruit capacity from a public cloud service provider to help them manage their data. However, while the cloud is a relatively cost effective, simple to manage, and scalable solution to suit your needs, it can also create some other challenges. Learn more.

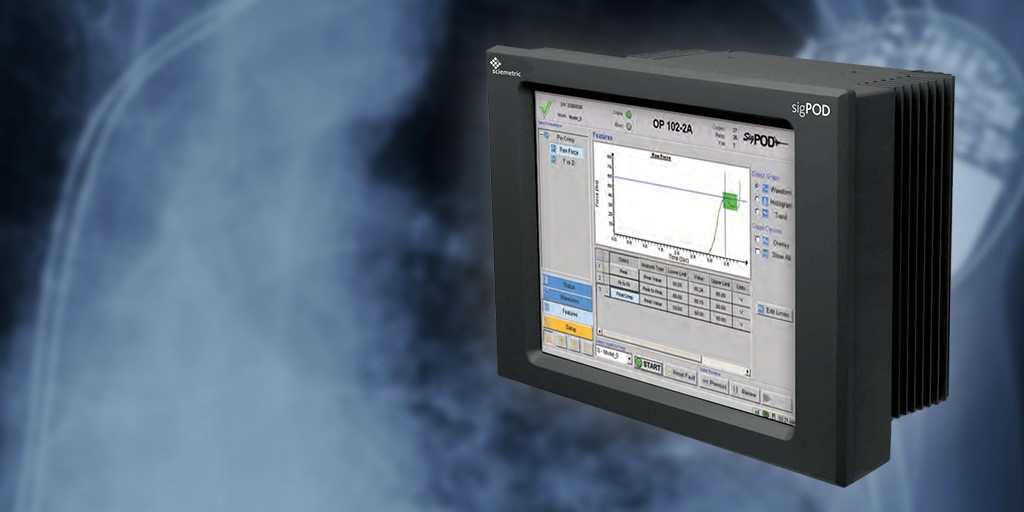

7 design considerations for an edge device meant for an industrial/manufacturing setting

5 ways to improve your production line in 2020

Improve crimp testing with non-destructive methods

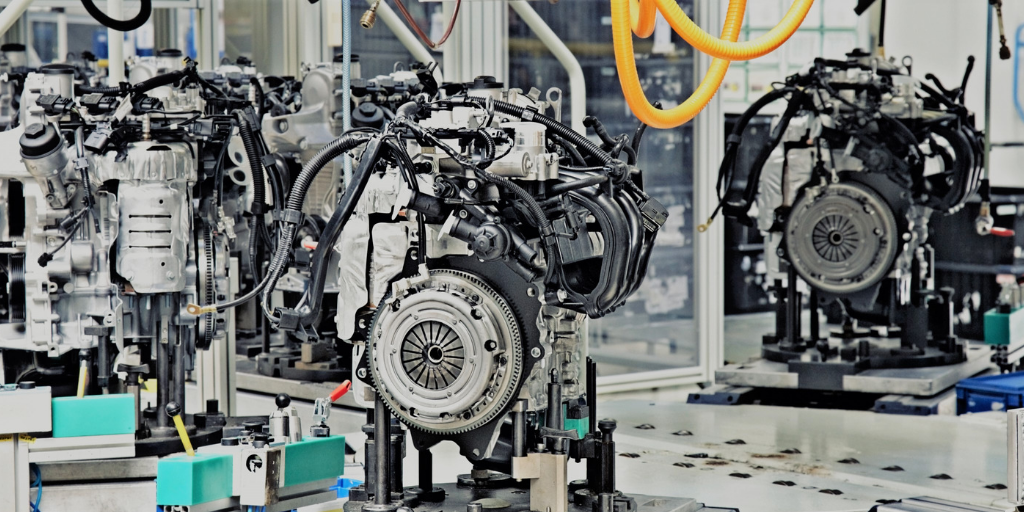

How to catch faulty fuel rail insertion with digital process signature analysis

Tearing down an engine to find a problem when it fails an end-of-line test is costly and time-consuming. It’s much better to identify a quality issue upstream on the production line where it occurs. Learn how an automaker used digital process signatures to adjust their fuel rail insertion parameters to catch faulty insertions before they reach the end of the line.

A more reliable weld test through data, without the need for destruction

The traditional approach to testing weld integrity is often destructive pull-test, with its shortcomings. Perfectly good assemblies may be ruined, while faulty ones can still slip through and be shipped for use. With digital process signature analysis, however, all the metrics that identify problems can measured to catch defective parts.

How to improve valve tappet set monitoring: A case study

The valve tappet setting application can have a huge impact on the overall quality of an engine. If the valve tappets are not adjusted and tightened within precise parameters during manufacturing, it can cause premature wear and excessive engine noise during operation. Learn how Sciemetric helped an automotive manufacturer boost quality and repeatability with an efficient solution for the valve tappet set station.