Collect and store the right manufacturing data

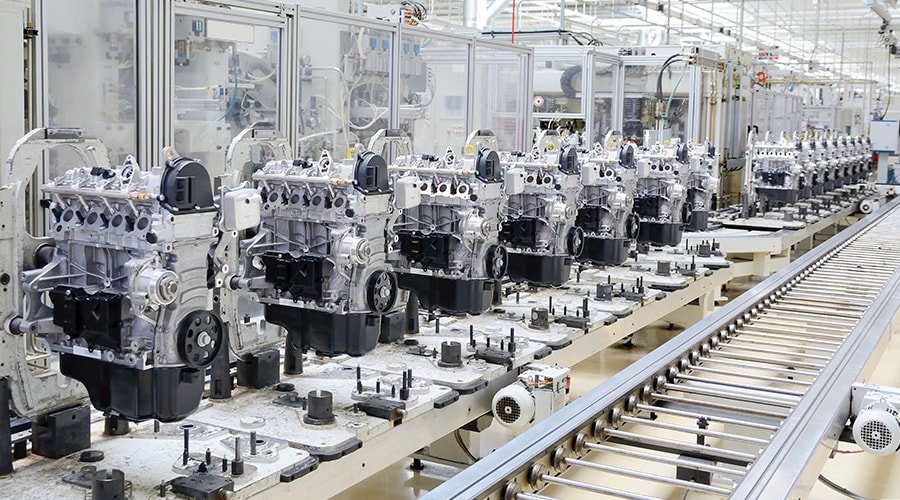

Discrete manufacturing production lines include dozens of processes and tests. Each station can generate terabytes of data every day, in its own database. How do you consolidate these data silos and how do you know which is the right data for useful analytics?

Get the help of Sciemetric data experts. Our engineers can design and deliver the right data solution for you – from useful data collection and consolidation for enterprise-wide view, to data storage and retrieval that is a perfect fit to your existing enterprise infrastructure.

Based on your specific requirements, our Applications team can set up a custom data management and reporting strategy that is a complete line-wide solution and can include the following:

- System assessment, system architecture, and server specifications

- Collection and storage of the data types that matter to you (including scalar points, digital process signatures, and even images from machine vision systems)

- Consolidation of all data types into a single source, from all the DYI or 3rd-party systems on your line, and all proprietary tests and process machines across the plant

- Database backup, archiving and optimization

- A suite of tools and know-how for data analysis to preempt or resolve issues and improve operations