Advanced Product Features

- Wall mount configuration 9” W x 6.5” H x 7.25” D

- Powerful 32-bit processor & 24 –bit A/D converter

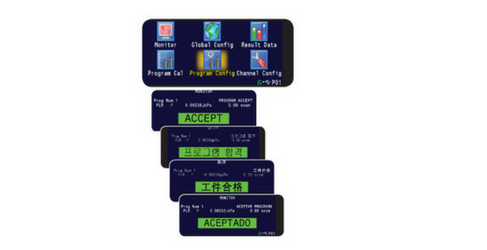

- Language neutral color LCD 6 line 480 x 136 operator display

- Bar Graph display (pressure, loss, or flow)-English, Chinese, Korean, Spanish

- Individual LED Pass/Fail/In-test test status indicators

- Modular pneumatic and control packages

- Single test channel

Standard Features

- Auto Calibration includes mass flow leak standard certified for pressure and flow

- Transducer zero and span are automatically reset during auto calibration

- “Performance factor” calibration feedback ensures accurate results

- Manual edit of Calibration Program permitted

- Self Test isolates the test instrument pneumatics to verify a “no leak” condition

- Features ensure accurate results and easy operator setup and troubleshooting

- Firmware validation document included

Standard Test Pressure Ranges

Standard pressure transducer, valve manifolds, and regulator ranges:

-14.5, 15, 100 (PSIG)

- Optional High cV flow valves and manifold available up to 100 psig range allows 5 times faster fill and exhaust to reduce cycle times on large parts

- Absolute pressure transducer

- Two (2) point pressure calibration

- Data resolution 0.00001 psi/ and scc/m.

Selectable Test Units of Measure

- Pressure: PSIG, PSIV, inH2O, cmH2O, mmH2O, kg/cm2, ATM, inHg, cmHg, mmHg, kPa, Pa, MPa, Bar, mBar, Torr

- Flow: Sccm, sccs, scch, slpm, slps, slph, scfm, scfs, scfh

- Time: Sec, msec, min

- Units of measure can be instrument global or per test program

Tooling Control

- 6 inputs/3 outputs- 1in/1out “seal only” tooling motion - no feedback

- Tooling I/O is internally connected

- I/O 24 VDC – optional I/O cable “Cable,CTS, P56-540”

Test Data Storage

- Up to 5000 LIFO part results including Date / Time / Test Results

- SPC data tracking for part traceability

Electrical Requirements and Connectivity

- 88-264 VAC, 47-63 Hz or optional 22-26 VDC

- RS232(1)

- ¼” Colder fitting for test line attachment

Testing Technologies

Single Test Configurable for Pressure or Vacuum Decay Test Requirements

- Pressure/Vacuum decay-pressure change

- Pressure/Vacuum decay-with certified mass flow leak standard

- Pressure/Vacuum decay-pressure change/time

- Storage for 4 pre-programmed test sequences

- Test Program can be selected through keypad or binary input

- Test results evaluation is fixed (Fail/Pass/Fail)

- Test result output format is fixed

Selectable Test Parameters

- Quick Test

- Test Pressure Level Compensation

- Adjustable Environmental Drift Correction per test program