In-process automotive transmission testing enables you to monitor the quality of a part or component as it is being manufactured—when the time and cost required to address a defect is the lowest. The result is better quality, fewer repairs and, more importantly, fewer defective transmissions.

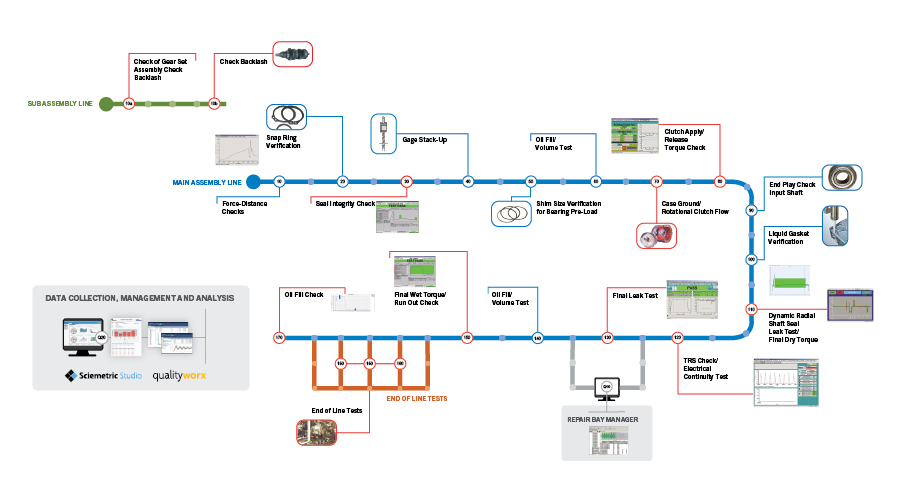

Sciemetric has solutions for the automatic and manual transmission manufacturing line for key test applications in assembly, sub assembly, and for end-of-line tests. Typical tests monitored on the transmission production line include:

- Gear quality verification

- Press operations on bushings, bearings, upper and lower bearings, cup plugs

- Output shaft torque to turn

- Torque and vibration test for gear mesh

- Leak testing

- End of line verification, including noise and vibration (NVH) checks

Process monitoring on your transmission manufacturing line

Sciemetric’s sigPOD is configurable to monitor virtually any test on your transmission manufacturing line to ensure product quality and catch defects before they even reach the end of the line—all in one universal solution across your plant.

Use our in-process monitoring solutions across the entire automotive manufacturing process, including:

Sub Assembly Line Testing: Gear set assemblies, and rotational gear set backlash check

Main Assembly Line Tests: Force-distance, snap ring verification, seal integrity, gage stack-up, shim size verification, oil fill/volume, case ground/rotational clutch flow, clutch apply/release torque, end play check input shaft, liquid gasket verification, radial shaft seal leak tests, TRS/electrical continuity, final leak tests, final wet torque/run out check

End of Line Tests: Final test stands check, oil fill check

Process data from each station on the transmission manufacturing line, including leak testing, torque checks, liquid gasket verification, and more, is captured using the sigPOD and made available using our PSV (process signature verification) software or data intelligence tools for more detailed analysis and reporting.

Data management and analytics solutions for transmission manufacturing

Achieve traceability and continuous improvement

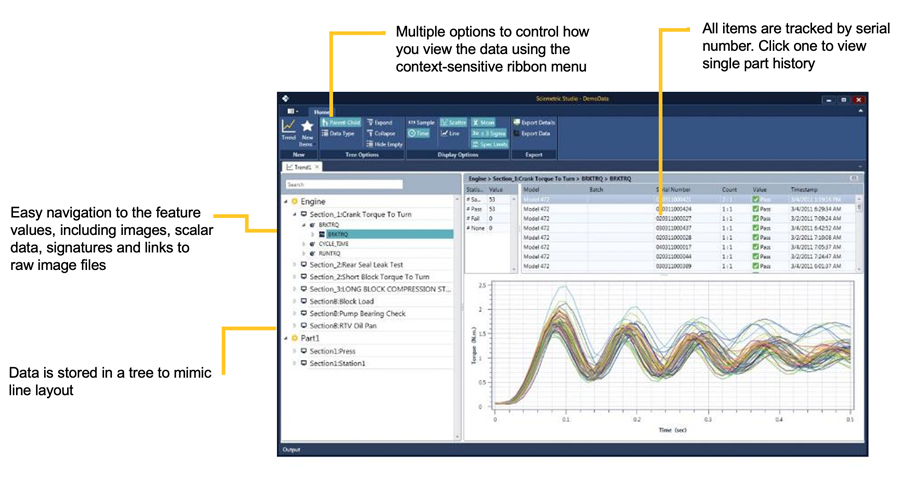

Using Sciemetric's QualityWorX data management and analytics solution, you can collect and store data from critical-to-quality stations on your transmission line, and other stations across your entire production line, including digital process signatures, scalar datapoints, and machine vision images. Data is stored by serial number and organized in a tree structure that mimics the line, making it easy to investigate defects or production issues.

This data is then made available for analysis and reporting using Sciemetric's data analytics tools in Sciemetric Studio. This capability provides advanced process analysis and defect detection by enabling complete traceability throughout the automotive transmission manufacturing process. The software’s comprehensive reports prove that your parts meet quality standards—down to the components within the final assembly.

This process analysis capability also offers the ability to achieve continuous improvement on your line, allowing you to identify and fix common problems occurring on your line so they don't continue to slow down production.

Images created by machine vision cameras that may be part of your line monitoring the application of liquid gasket sealant and snap ring insertion, for example, can also be collected, stored, and analyzed with QualityWorX Vision along with your other process data for a full view and comparison of production processes in one place.

LEARN MORE ABOUT SCIEMETRIC DATA COLLECTION & ANALYTICS

Case Studies

The below case studies provide a deeper look at a few examples of how our in-process testing and analytics technology has been applied to improve critical-to-quality stations on the transmission line.

Accurate NVH (noise, vibration, and harshness) testing for the transmission

Inconsistent transmission quality can cause unwanted noise and vibration, a common customer complaint. Sciemetric’s proven NVH test has been seamlessly integrated into manufacturers’ existing EOL test to detect issues such as valve noise, missing bearings, timing problems, gear, and loose rubbing parts. In addition, process data is centralized for complete traceability.

Turnkey solutions for transfer case shift actuator testing

Electronically operated transfer cases are difficult to test post-installation as it is unreliable and expensive, especially when defects are found. Sciemetric offers turnkey solutions for several test scenarios using signature analysis to detect and pinpoint defects in the transfer case (poor gear mesh, motor winding defects, and defective actuator), while accurately determining root-cause(s).

Benefit from our decades of experience on the transmission line

With decades of experience putting our in-process testing and data analytics solutions to work for automotive manufacturers, our team is equipped with the knowledge and expertise to provide you with unique options to help you optimize your specific equipment and manufacturing process. Our customers achieve many benefits on their line, including improved product quality and process efficiency, and fewer defective transmissions or warranty claims.