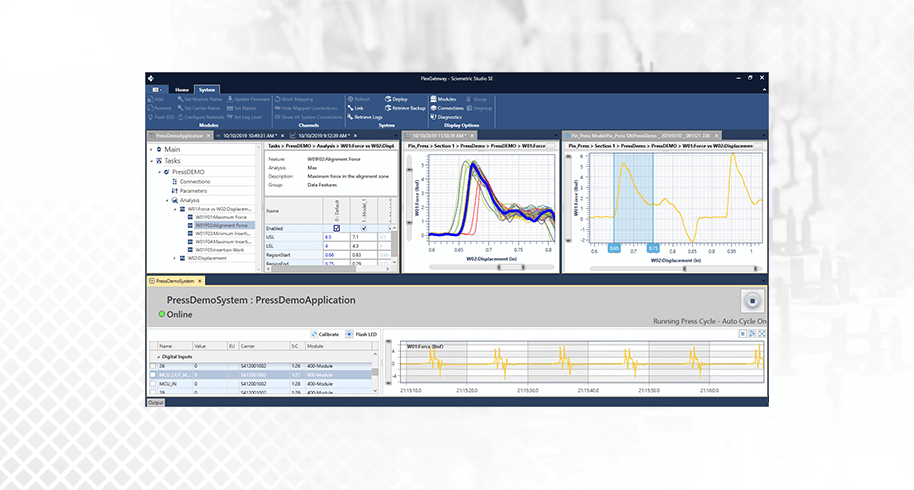

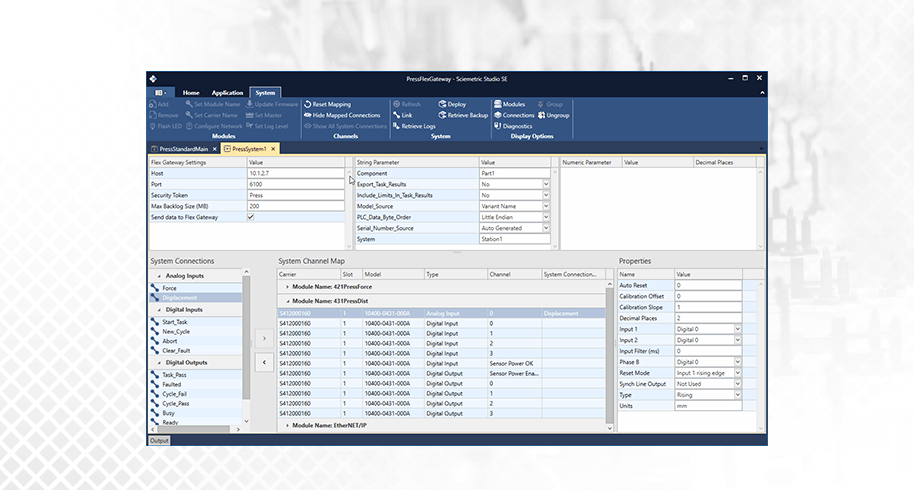

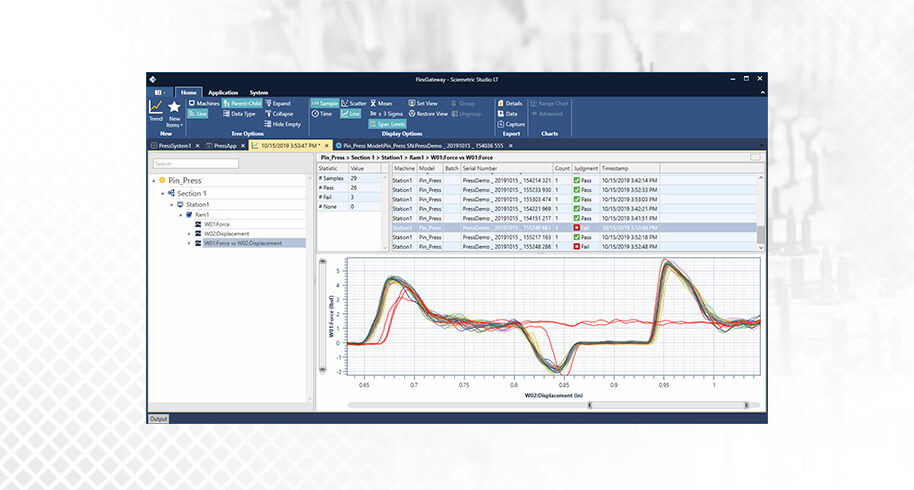

Sciemetric EDGE is a universal industrial analytics platform that can help you digitize and perfect your processes in record time. Comprised of intelligent hardware and software, the platform offers a sophisticated and exciting way to monitor up to 40 channels of data, perform real-time pass/fail control, and gain the visibility required to optimize and control the overall process. These processing, analytics, and control functions are remotely configurable, providing you with centralized management of your distributed operations. Sciemetric EDGE is IP65 rated, designed for harsh environments.

The Sciemetric EDGE IIoT platform uses digital process signature analysis to provide in-depth insight into the performance, reliability, and repeatability of industrial applications. Facilities across a wide variety of industries trust our flexible process monitoring and control systems for discrete manufacturing, process manufacturing, condition and machine monitoring, and data acquisition and measurement.

REQUEST A QUOTE ON SCIEMETRIC EDGE