Sciemetric has extensive experience in the automotive and off-highway engine manufacturing industry, and we continue to provide the same quality testing and monitoring capabilities for the electric vehicle manufacturing market. Our flexible solutions are equipped to meet the needs of electric vehicle testing and monitoring to ensure quality and traceability on the production line.

Sciemetric has technologies for a variety of applications on the electric vehicle manufacturing line, from battery testing to electric drivetrain manufacturing and electric motor assembly. Learn more about each below.

EV Battery Testing

Battery testing is an important part of the manufacturing process for electric vehicles. Sciemetric’s in-process monitoring and leak testing solutions are ideal to make sure your batteries are fastened properly and functioning as per integrity standards.

Leak Testing for EV Batteries

The Sentinel 3520 is a powerful tool for leak testing on your electric battery manufacturing line. The leak test on the battery production line can include helium vacuum testing and sniffer leak testing for cooling and refrigerants.

Together with Sciemetric’s partner, Cincinnati Test Systems, we will provide a solution to ensure the integrity of the seal in every component of the battery; from the battery container down to the battery cell, to ensure the performance and lifespan of batteries to be installed in electric vehicles.

Fastening for EV Batteries

The manufacturing of an EV battery requires precise and consistent assembly processes. Run-down operations must be monitored for proper application to avoid causing more problems further down the line. Each battery has dozens of run-down operations and critical process that need to be monitored separately. Sciemetric collects the process data from each operation and then stores this data in the QualityWorX database, where it becomes accessible as part of a consolidated birth history record for each component and assembly on your line.

Bead Dispense Monitoring for EV Batteries

The manufacturing of EV batteries can include several bead dispense applications, including RTV silicone and other sealants. These dispense processes must be monitored for quality and consistency after each application. Sciemetric monitors the dispense process, checking for back pressure, voids, gaps and bubbles. This data is then delivered to QualityWorX as part of a consolidated birth history record, providing access to process data and machine vision images in one centralized database.

Machine Vision for EV Batteries

Machine vision is often used throughout the EV battery production line to monitor and inspect surface applications for quality and consistency. This includes seals, weld and dispense quality, surface and contour inspections, component presence and more. Sciemetric’s QualityWorX Vision software offers an effective way to collect, retrieve and analyze these machine vision images and associated data collected from your production line, in one consolidated database.

By collecting this data in one database across your enterprise, you are able to access a detailed birth history for each battery on your line in seconds. Learn more about how our QualityWorX Vision software could help you break down the data silos in your factory and make better use of your machine vision images and data.

Electric Motor Assembly

As electric vehicle technology has become an increasingly important focus for the automotive industry, so too has it become an important focus for Sciemetric. We continue to provide leading process monitoring and testing solutions for the automotive manufacturers, as we have for decades.

We provide a variety of solutions for quality testing and monitoring of the electric motor assembly, including stator coil winding, contact ring assembly, rotor magnet assembly, rotor balancing, and rotor magnetizing.

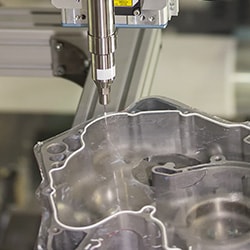

Electric Drivetrain Assembly

Sciemetric has quality testing and monitoring solutions for virtually any test for the electric drivetrain, including bearing press, press-fit monitoring, RTV dispense monitoring, fastening and torque checks, thread verification, and leak testing.

CONTACT US TO LEARN MORE ABOUT OUR

MANUFACTURING SOLUTIONS FOR ELECTRIC VEHICLES