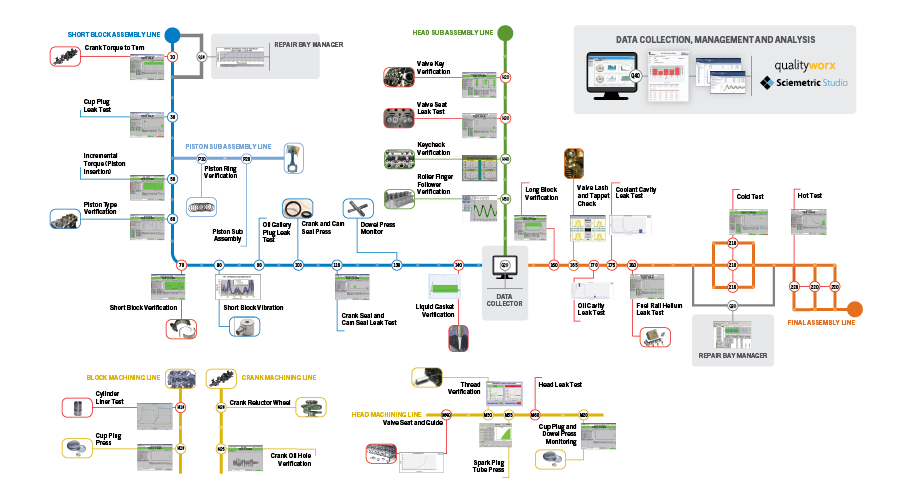

Sciemetric’s ISD (Integrated Systems Division) offers flexible, customizable services and solutions to meet your needs. Anything from a small test cart to a full turnkey machine; we will manage every stage of the design, build, and integration process to deliver a solution that meets your needs, on-time and on-budget.

Sciemetric ships and installs turnkey systems around the world, with local support located across USA, Canada, Mexico, India, China, UK, and Europe. Working with Sciemetric technology, or any technology, our ISD group will collaborate with your team to identify your needs and bring the project to life.