IIoT / Smart Manufacturing

Digital process signature analysis: The first step to Industry 4.0

Many manufacturers continue to focus on data collection rather than data utilization. They don't yet have the modern data analytics tools in place that will allow them to squeeze from their part data the actionable insight that is crucial to meeting Industry 4.0 benchmarks they are seeking for quality, yield and traceability. Learn why digital process signatures are your first step to meet Industry 4.0 objectives.

Factors in identifying proper test pressure for your leak test

A chief goal when it comes to optimizing any leak test is to ensure if the cycle time of the test can keep up with the pace of production. One factor in optimizing the test so that it can cycle as many parts as quickly as possible with an acceptable range of repeatability and reliability is test pressure. Consider the following factors when identifying proper test pressure for your leak test.

How to effectively store and manage machine vision images and data

The information generated by machine vision systems puts a whole new spin on the term “big data.” The raw image files output from vision systems are huge, and manufacturers can generate terabytes of image data in a month—even in a week! So, what do you do with all this data? Read more to find out!

Choosing the right camera for your vision inspection

Are your machine vision needs on the production line better served with a smart camera, or a “dumb,” more basic one? Before you make the investment, consider these factors that can dictate which option is better for a given situation.

5 tips to improve your production line in 2019

With each new year, many of us take time to reflect on our past and set goals for the future. Why not apply the same exercise to your production line? To help you improve your production line in 2019, we have provided the following tips, chock full of insights from our experts.

Manufacturing analytics: So you’re collecting data, but can you use it in a recall?

It’s when manufacturers are faced with a recall or warranty claim that they realize data collection alone has little value if they can’t easily access and analyze it. Learn how we helped one manufacturer of agricultural machinery use their data to improve their root cause analysis time from weeks to minutes!

Smart cameras: Unlocking the ROI trapped in the black box

A smart camera or machine vision system can do so much more than basic, "dumb" cameras—but many manufacturers don't take advantage of their full capability in terms of data analysis. That’s where the opportunity arises to generate a strong return on your machine vision investment, unlocking the full potential of the "black box".

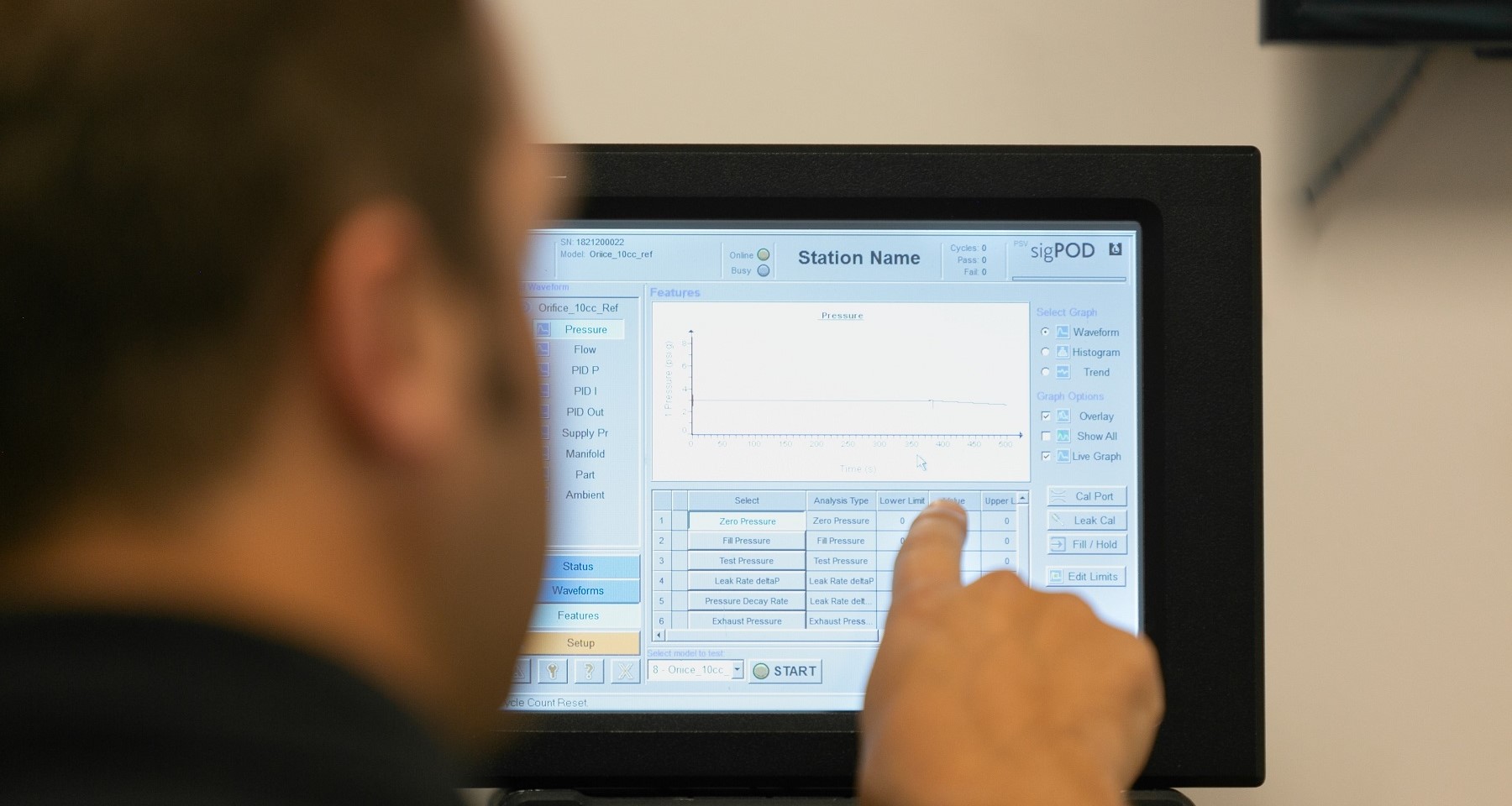

Data visualization and analysis provides double-digit gains in leak test cycle time and FTT

Many manufacturers face the costly problem of a lagging leak test cycle time. With constant pressures on production, line managers have no choice but to run parallel test stations to maintain production quotas. More often than not, the answer is simple—use your leak test data. Here’s how one customer did it.

Want to improve your manufacturing processes? Rethink your machine vision data management strategy

Machine vision images and data are a valuable part of the Manufacturing 4.0 equation. The problem is that machine vision images and data are often trapped in silos across the plant floor, with images stored in formats that make them difficult to access and analyze. With the right data management strategy, you can make this data accessible to your team so it can drive value.

Is machine vision data part of your IIoT strategy? It should be.

Machine vision images and related data can be used for much more than basic pass/fail determination during the process cycle. We get into how this data can be collected, correlated and analyzed will all other production data as part of a comprehensive IIoT strategy.