Data Management & Analytics

5 tips to improve production line efficiency in 2022

Checklist: Choosing a manufacturing data management and analytics platform that delivers real ROI

Having collected data is not of much help when you lack the tools to retrieve and analyze the data to quickly trace root cause when quality issues impact production. Here are some key considerations that will help you find a manufacturing data management and analysis platform that will get your data working for you.

5 considerations when automating your quality control process on the manufacturing line

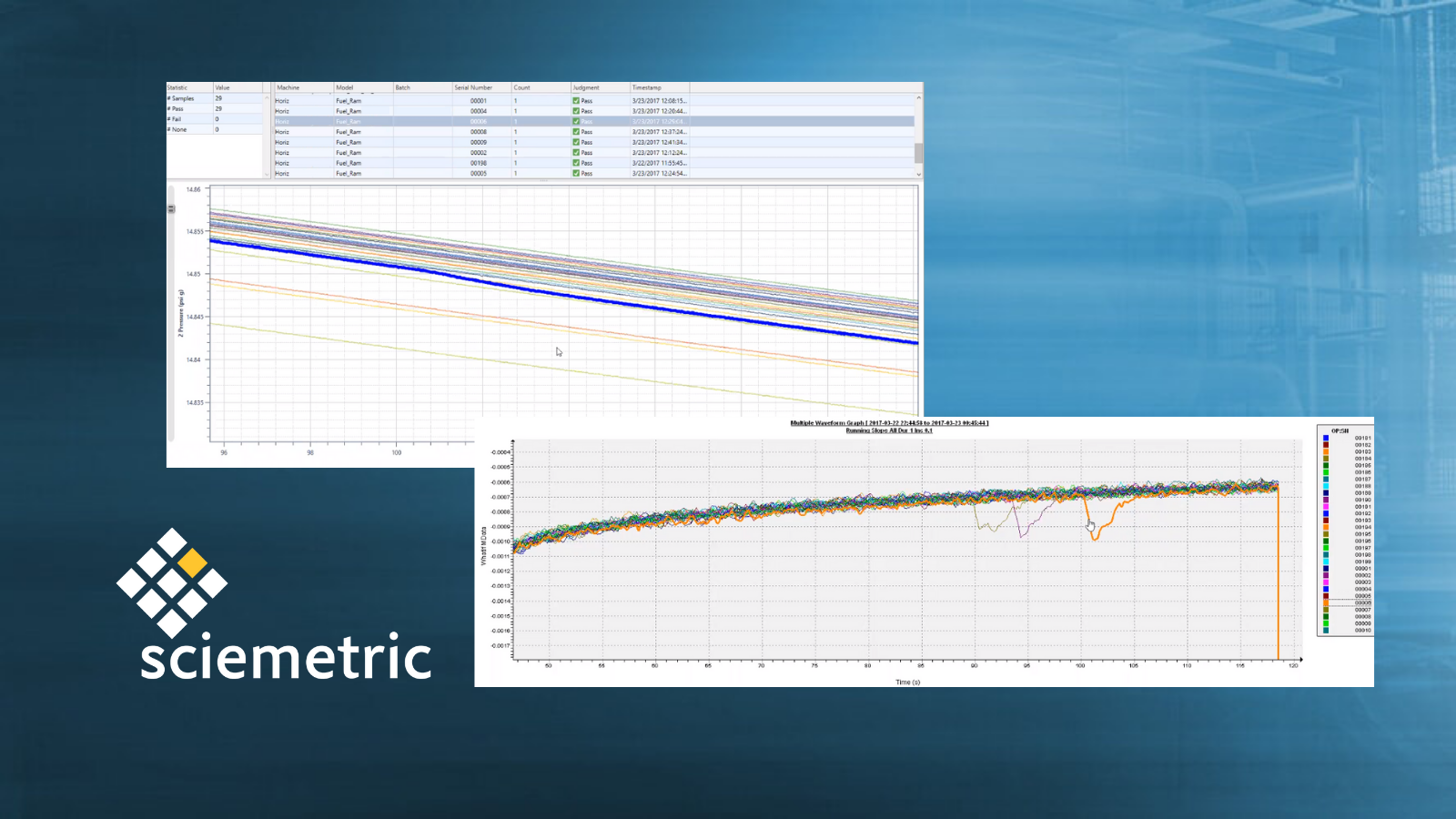

Sciemetric data analytics tools enabled engine manufacturer to link EOL failure to cracked check valves—see how!

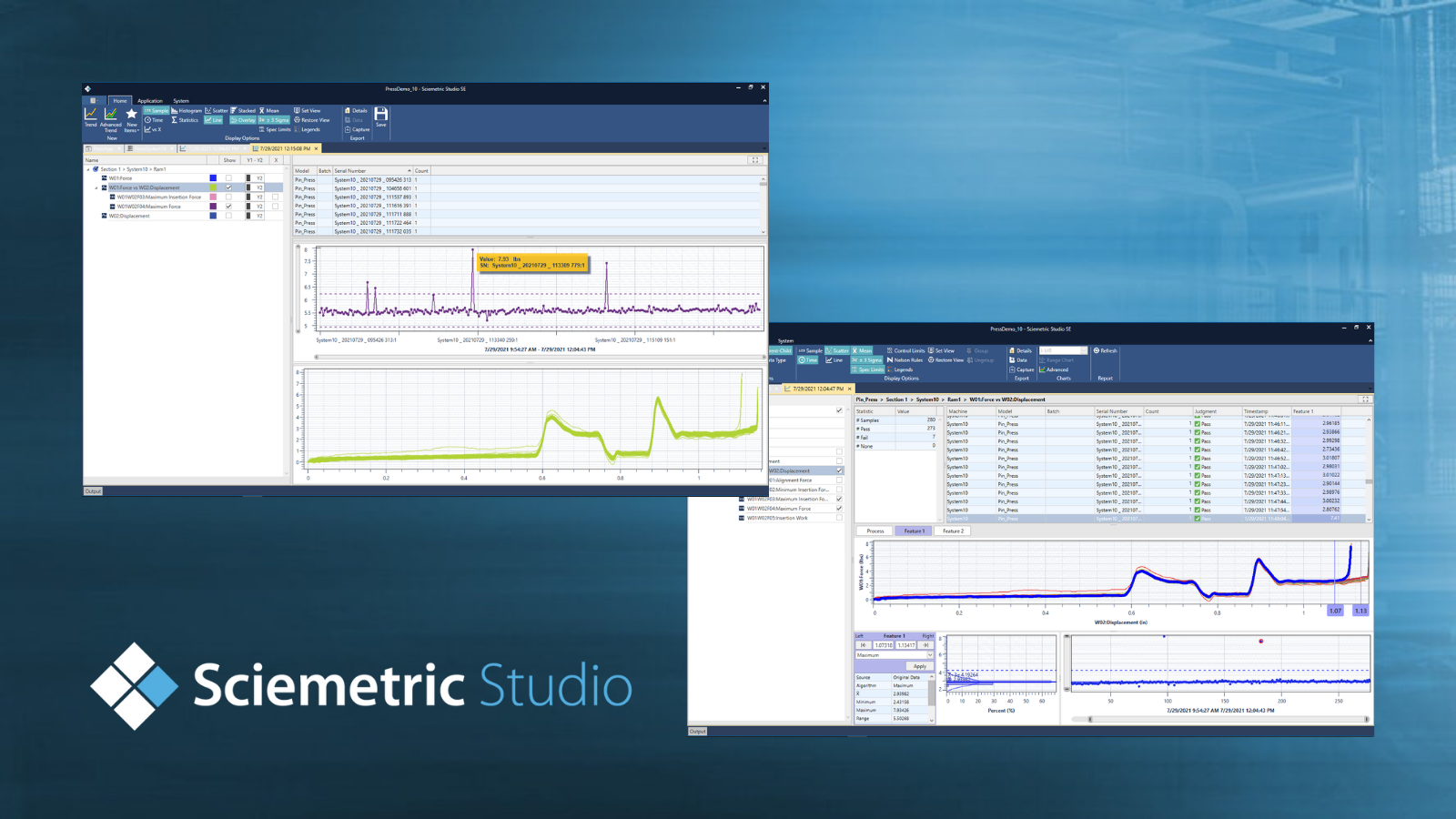

3 new ways to use Sciemetric Studio to improve your production line

4 ways to make better use of data from stations on the production line

Data is everywhere on today’s production lines. The challenge is that though manufacturers may be collecting large volumes of data, it often isn’t being used proactively or efficiently to solve day-to-day problems. Consider the following best practices to start making better use of your production line data.

Considerations when digitizing paper-based records, automating defect detection and quality control on the production line

7 production data gaps that are slowing down manufacturing engineers

Monitoring for weld expulsion: A prime cause of weak welds, defects

Set up your line for success in 2021: Lessons for improving product line efficiency and effectiveness

Due to the circumstances of 2020, manufacturing budgets and timelines have been under an ever-increasing microscope. This sentiment certainly rings true when we looked back at the most-read content from our blog over 2020, where improving efficiency and effectiveness seem to be top-of-mind. Set your line up for success in 2021 with these tips from our most-read posts of 2020, here!