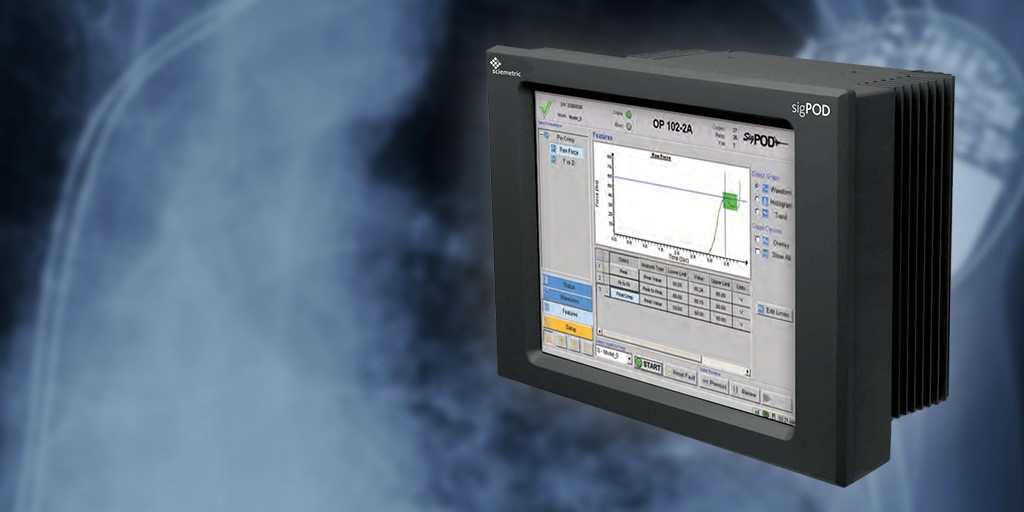

Press-Fit 101, Part 1: How to improve defect detection during press operations

Like any common manufacturing operation, a press-fit must be monitored to prevent flaws and defects from impacting part quality. In this series, we will dig into how press defects can be found using digital process signature analysis software, what to monitor in a press operation and also provide examples from actual press operations.

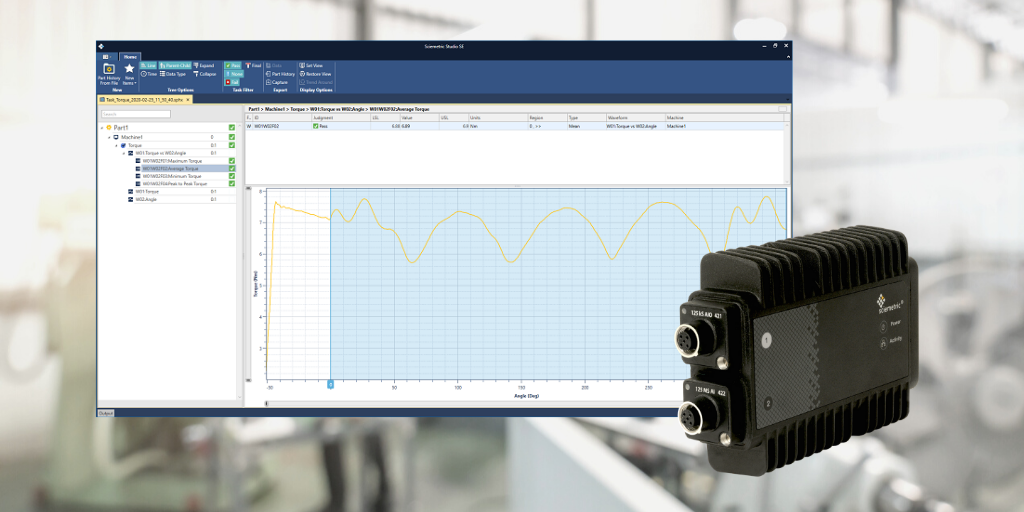

Torque-to-Turn Testing 101, Part 2: The most important feature checks to identify torque defects

Torque-to-Turn Testing 101, Part 1: How to identify defects during torque test

The first post in a two-part series, this post discusses how digital process signature analysis offers you accurate and effective defect detection during torque test. With parts that are meant to turn or rotate, how easy or how difficult it is to initiate that movement can reveal issues with the manufacturing operation, which digital process signatures can help you identify proactively.

5 ways to improve your production line in 2020

Sciemetric EDGE proves its powerful monitoring flexibility—ensuring popcorn quality!

Battery pack leak test: The challenges of getting an honest result

A variety of factors make it difficult to simulate the exact leak conditions battery packs will experience in the field, but there are strategies to achieve an effective battery pack leak test. Here are two of the key challenges you are likely to encounter with battery pack leak testing and strategies to overcome them.

Improve crimp testing with non-destructive methods

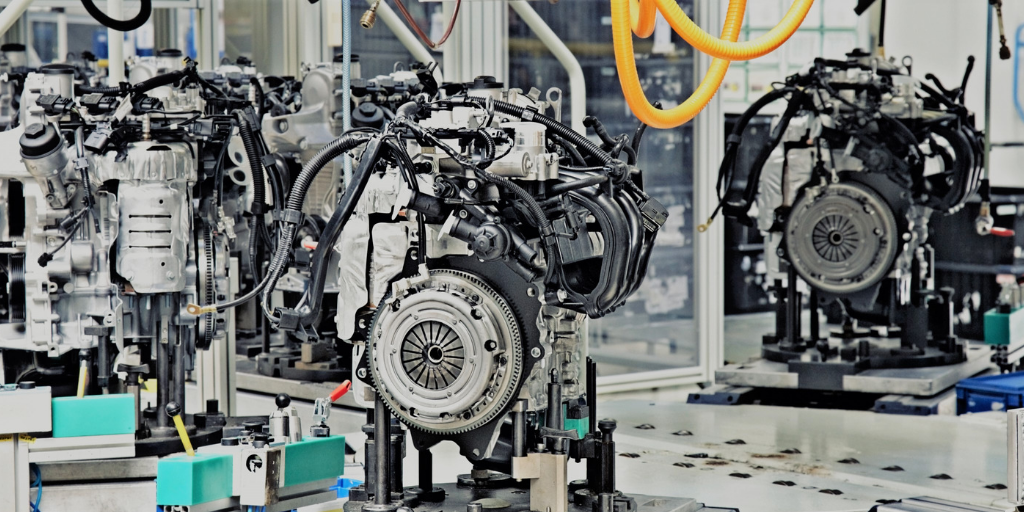

How to catch faulty fuel rail insertion with digital process signature analysis

Tearing down an engine to find a problem when it fails an end-of-line test is costly and time-consuming. It’s much better to identify a quality issue upstream on the production line where it occurs. Learn how an automaker used digital process signatures to adjust their fuel rail insertion parameters to catch faulty insertions before they reach the end of the line.

A more reliable weld test through data, without the need for destruction

The traditional approach to testing weld integrity is often destructive pull-test, with its shortcomings. Perfectly good assemblies may be ruined, while faulty ones can still slip through and be shipped for use. With digital process signature analysis, however, all the metrics that identify problems can measured to catch defective parts.

How to improve valve tappet set monitoring: A case study

The valve tappet setting application can have a huge impact on the overall quality of an engine. If the valve tappets are not adjusted and tightened within precise parameters during manufacturing, it can cause premature wear and excessive engine noise during operation. Learn how Sciemetric helped an automotive manufacturer boost quality and repeatability with an efficient solution for the valve tappet set station.